Related Links:

Welded vs. Woven Wire Mesh

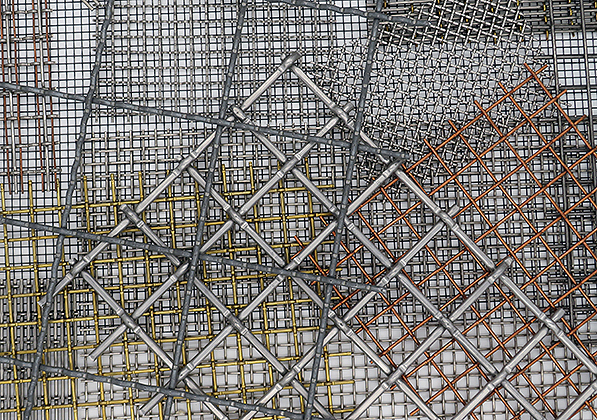

As our Wire Cloth Stock page mentioned, Wire Mesh incorporates thicker wire diameters starting around .063″ with a noticeable larger opening beginning around .25″. As a result, this type of material is both strong and rigid perfect for heavier-duty applications such as aggregate screening and architectural fencing.

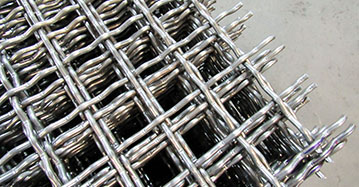

Welded Wire Mesh is manufactured through a process of resistance welding using multiple welding heads. This process fuses the wires together at every single intersection. In other words, the openings will remain the same, permanently, throughout even the most demanding of processes. It will also continue to provide consistent results throughout processing since the wires cannot move and thus maintain their same openings.

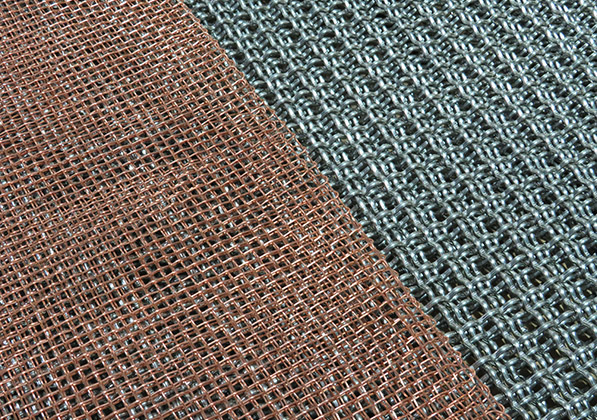

Woven Wire Mesh as the name implies, incorporates a weaving pattern as one wire passes over and then under the next repeatedly. There are a variety of weave styles to choose from each with a different look. Additionally, a variety of metals & alloys including exotic types can be woven such as Brass, Copper, and Aluminum.

Wire Mesh Benefits

Both Welded & Woven Wire Mesh has substantial advantages, especially when compared to other similar products such as Perforated and Expanded metals.

- Openings: Wire Mesh can also have a larger opening in either a square or rectangular orientation.

- Functionality: To that end, a more significant open area percentage can allow for increased production capacities and greater material flow.

- Aesthetic: Completely different visual appearance.

- Options: Various metals & alloys are available for a woven preference.

For additional details on construction styles please check out our specifying page. Similarly, as you navigate our website you will easily view information about each mesh type along with applications, material specifications, and weaving capabilities. Furthermore, helpful resources such as images, videos, and sample kits are also available for your review.

Comprehensive Inventory

Our comprehensive inventory of both wire cloth and wire mesh spans from a sizable 4” opening to an ultra-fine 635 cloth with everything in between. Encompassing nearly 30,000 sq. ft of our main headquarters in Morrisville, Pennsylvania we warehouse countless rack space of various superior metals and alloys in a wide range of mesh styles, mesh counts and openings. If you are looking for an item in Market Grade, Filter Grade, Mill Grade, Tensil Bolting Cloth, Space Cloth or something larger woven or welded we likely carry it or can source it for you!