Standard Mesh Construction Styles

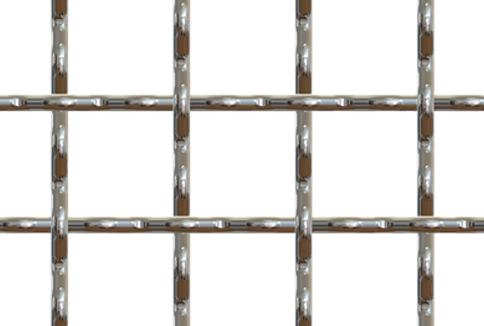

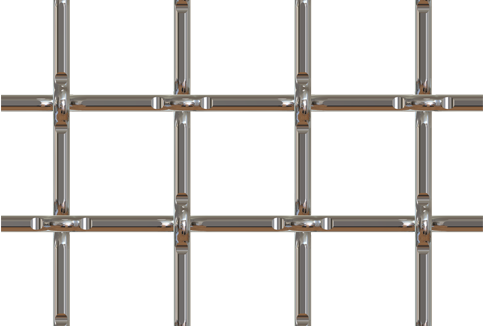

Plain Weave

This standard weave style is constructed with interlacing wires at every intersection. Plain Weave is mostly common in Wire Cloth where moderate or small openings are needed for general screening applications.

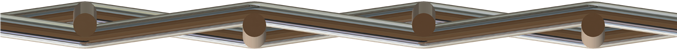

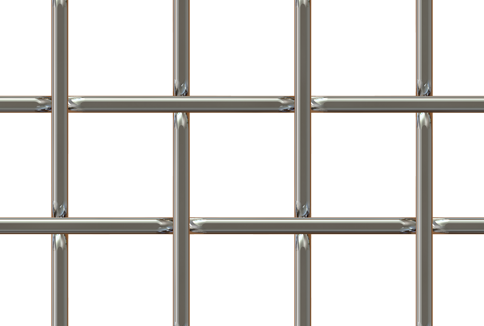

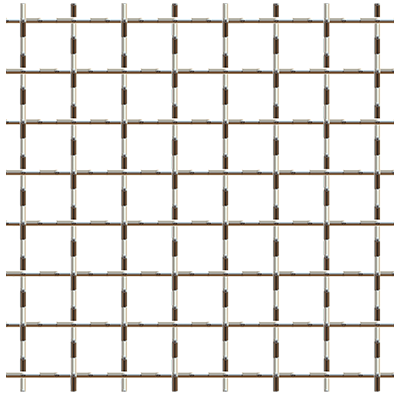

Intermediate Crimp

This weave style is a variation of plain weave where more defined crimps are placed on the material. Wires are placed on odd numbers crimps 3rd, 5th, 7th, etc to create a unique opening. This attractive-looking mesh is often used in architectural applications.

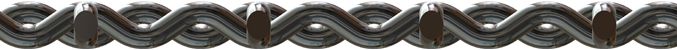

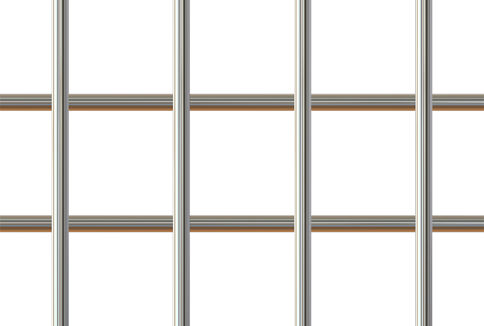

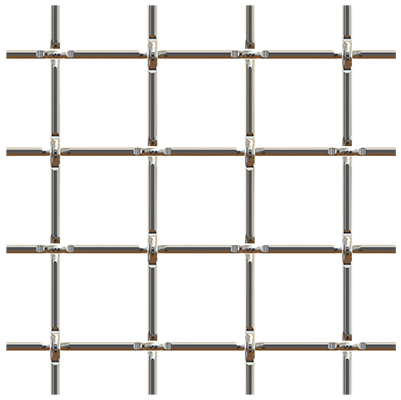

Lock Crimp

This weave style creates a tight wire joining at each intersection that resists movement also know as “racking”. Lock Crimp has very accurate opening dimensions and is commonly used in fencing and security applications.

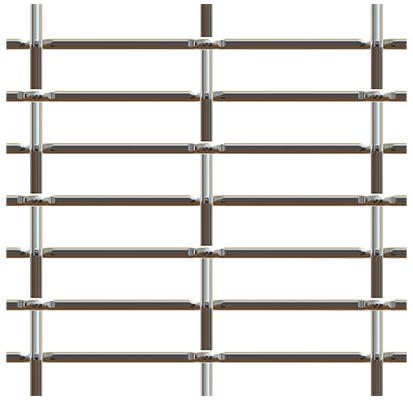

Flat Top

This weave style has all the crimps on one side giving the other side a smooth surface. This style also has less resistance to material flow as well as an aesthetic appeal.

Welded

Welded wire mesh has intersecting rows and columns of wire that are resistance welded at the intersection to form a grid. Because the wires are fused together, the mesh is incredibly strong and rigid ensuring a long-lasting product.

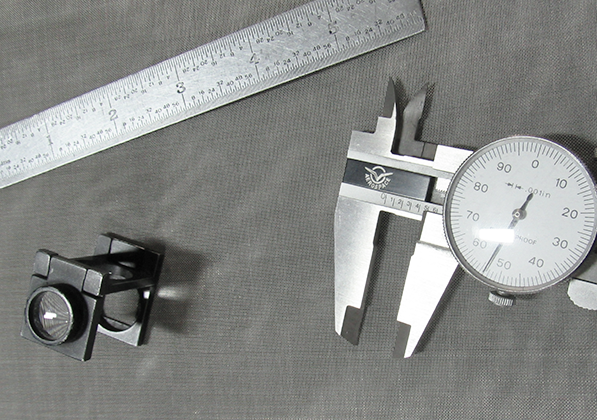

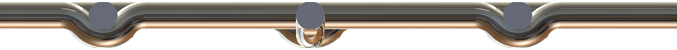

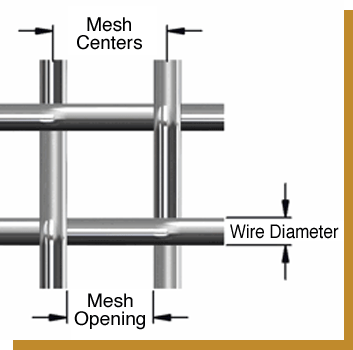

Measurements

- Mesh Centers – (C) Refers to the center of one wire to the center of the next parallel wire.

- Wire Diameter – (D) Refers to the measurement of the entire wire from one side to the other. This is usually expressed as a number within three decimal places.

- Mesh Opening – (O) Refers to the measurable distance between two parallel wires.

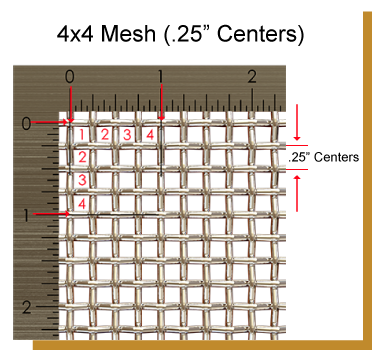

- Lineal Inch – Refers to the measurable distance in one inch.

- Mesh Count (MC)– Refers to the number of openings that can be counted in one lineal inch.

Formulas

To find the Mesh Opening if the Mesh Count and Wire Diameter are known:

1 – (Wire Diameter • Mesh Count) / Mesh Count = Mesh Opening

To find the Mesh Count if the Mesh Opening and Wire Diameter are known:

1 / (Mesh Opening + Wire Diameter) = Mesh Count

To find the Mesh Centers if the Mesh Count is known:

1 / Mesh Count = Mesh Centers

To find the Mesh Centers if the Mesh Opening is known:

Mesh Opening + Wire Diameter = Mesh Centers

To find the Mesh Opening if the Mesh Centers are known:

Mesh Centers – Wire diameter = Mesh Opening

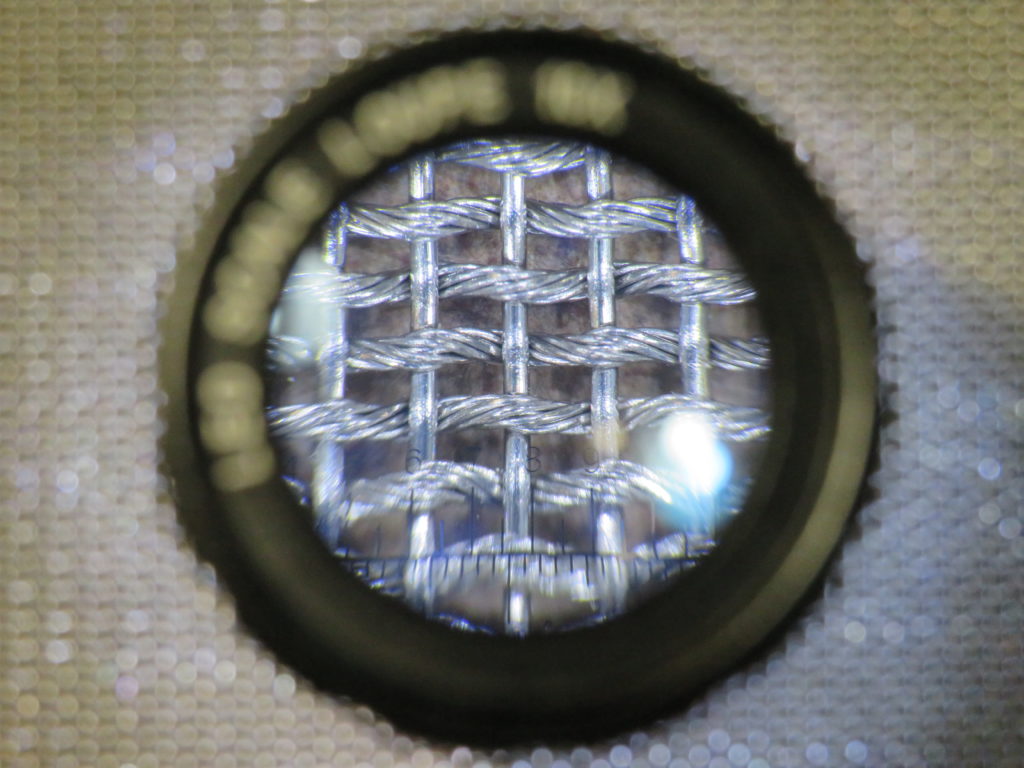

Wire Cloth – Ultra Fine & Fine Openings – Micron Retention

Though difficult to view with the naked eye, fine wire cloth have exceptionally small openings. Referred to as Micron, many applications require this single opening to be extremely accurate.

Absolute Micron Retention is calculated using the numerical equivalent of a millimeter (.03937). Note: The resulting answers may not be an exact match to a particular mesh specification, but there will be close available alternatives.

If the mesh opening is known divide the opening by the millimeter:

O / .00003937 = Micron

- A 200 x 200 Mesh .0021″ dia. wire has an opening of .0029″.

- .0029 / .00003937 = 73.66 or 73.7 Microns

If the desired Micron is known multiply the desired Micron by the millimeter:

__ • .00003937 = Opening

- Desired is a 260 Micron

- 260 • .00003937 = .0102

- A specification of/near .0102″ opg is needed

- A 60 x 60 Mesh .0065″ dia. wire with an opening of .0102″ is an option.

Percentage of Open Area

The percentage of open area in wire cloth and wire mesh is the ratio of the total open area of all of the openings combined relative to the entire screens area.

Applications that involve a required flow rate, as in material sizing, the flow of air, liquid or even the luminescence of light that passes through, the Percentage of Open Area is used to determine which specification will be best suited to a particular application.

Wire Cloth – Small & Medium Openings – Mesh Count

Method #1 – If the Mesh Opening is unknown:

(1 – MC • D)² * 100 = OA%

- 4 • .047 =.188

- 1 – .188 = .812

- .812 • .812 = .6593

- .6593 • 100 = 65.93

- Open Area % = 65.93%

Method #2 – If the Wire Diameter is unknown:

(O • MC)² * 100 = OA%

- .203 • 4 = .812

- .812 • .812 = .6593

- .6593 • 100 = 65.93

- Open Area % = 65.93%

4 x 4 Mesh .047” Wire Diameter

.203” Opening

Open Area % = 65.93%

Wire Mesh – Larger Openings

Space Formula

1″ Opening .120″ Wire Diameter – Lock Crimp

Open Area % = 79.72%

For Wire Mesh when the mesh opening and wire diameter are known:

(O / O + D)² • 100 = OA%

- 1.00 + .120 = 1.120

- 1.00 / 1.120 = 0.892

- 0.892 • 0.892 = .797

- .797 • 100 = 79.72

- Open Area % = 79.72%

Square Centers

1/2″ Centers .063″ Wire Diameter – Intercrimp

Open Area % = 76.40%

For a square opening when the mesh centers and the wire diameter are known:

(C/D – 1)² / (C/D)² • 100 = OA%

- .500 / .063 = 7.937 – 1

- 6.937 • 6.937 = 48.115

- .500 / .063 = 7.937

- 7.937 • 7.937 = 62.996

- 48.115 / 62.996 = .764

- .764 • 100 = 76.40

- Open Area % = 76.40%

Rectangular Opening

2″ Opening x .50″ Opening

.162″ Wire Diameter

Lock Crimp x Plain Weave

Open Area % = 48.84 %

For a rectangular opening use the centers for each opening direction (large and small) as well as the wire diameter:

(C/D – 1)² / (C/D)² • (C/D – 1)² / (C/D )² • 100 = OA%

- Mesh Opening + Wire Diameter = Mesh Centers

- 2.162 / .162 = 13.346 – 1 = 12.346 • 12.346 = 152.420

- 2.162 / .162 = 13.346 • 13.346 = 178.116

- .662 / .162 = 4.086 – 1 = 3.086 • 3.086 = 9.525

- .662 / .162 = 4.086 • 4.086 = 16.695

- 152.420 / 178.116 = 0.856

- 9.525 / 16.695 = 0.571

- 0.856 • .0.571 = 0.488 • 100

- Open Area % = 48.84%