Universal Wire Cloth produces vibrating, sifter, and shaker screens in both standard and custom options. Our quality and materials are of the highest caliber, and we can also offer cost-saving suggestions. Our screen sections will meet or exceed all leading manufacturers, including the O.E.M.

If you have any questions or need recommendations on your current or future project, contact one of our friendly, helpful representatives today. We can help guide you through your options regarding quality, cost, production yield, and any other questions.

This article will discuss the different uses of vibrating, sifter, and shaker screens. While the three options serve a similar purpose, each has unique capabilities that offer advantages to specific industries and use cases.

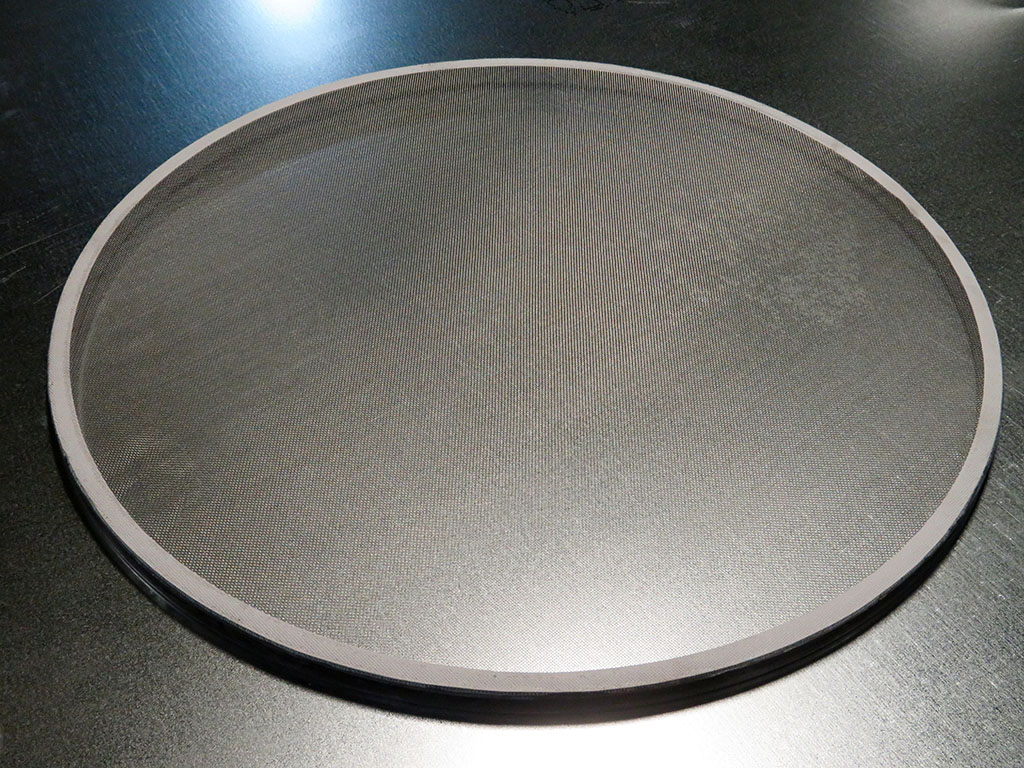

Vibrating Separator Screens

Vibrating Separator Screens are a type of screen section with a rectangular frame or a tubular ring size ranging from 18″ to 72″ in diameter. In most cases, the frame itself is quite durable and can be reused many times. With our OEM replacement option, we can remove the old material from your preexisting frame and re-screen it with new mesh as a great cost-saving option.

The construction process takes a wire mesh blank stretched and measured to the proper tension. Adhesive is then added to the screen frame and raised to meet the mesh. Finally, we remove excess material.

This type of screen will vibrate and shake, separating dry, free-flowing material through it.

Some of the most common industrial applications of vibrating screens include:

- Mining: The mining industry uses vibrating screens for separating minerals and other materials based on size and shape.

- Aggregate processing: The aggregate processing industry, operates with many heavy-duty vibrating screens for sorting and separating sand, gravel, and stones of different sizes.

- Food processing: The food processing industry uses vibrating screens for separating food particles and grading materials based on size and shape.

- Chemical processing: The chemical processing industry employs vibrating screens for separating and grading chemicals based on size and shape.

- Recycling: The recycling industry uses these screens for sorting and separating different materials, such as plastic, paper, and metal.

- Pharmaceuticals: The pharmaceutical industry untilizes vibrating screens for separating and grading powders and granules based on size and shape.

- Pulp and paper: The pulp and paper industry uses these screens for separating fibers, fines, and other materials based on size and shape.

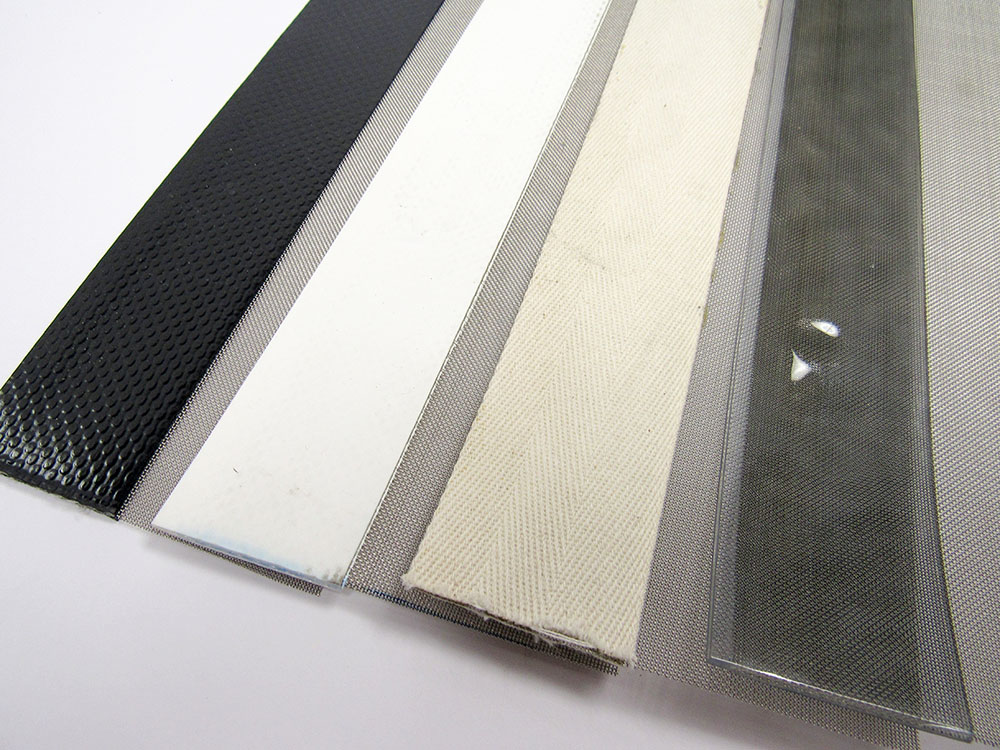

Sifter/Edged Screens

Sifter/Edged Screens are a type of screen section that has edging material secured to it. These include metals, plastic, vinyl, or canvas, with options like grommets that pull the screen tight. A variety of mesh materials are available, such as stainless steel.

Sifter/edged screens separate your “wanted” materials or particles from unwanted ones. The screen can also help people characterize the particle size distribution for a sample.

The construction process for sifter/edged screens begins with the meticulous inspection and precise cutting of Wire Cloth. Edging material is then skillfully heat-sealed to both edges of the metal, ensuring the creation of a sturdy frame. Additional options such as center and wear strips are also available.

Additionally, installing round or oval grommets further enhances the screen’s durability and functionality. As a finishing touch, unique label opinions that feature material specifications are available for identification purposes.

The following industries use Sifter Screens:

- Pharmaceutical

- Chemical

- Agricultural

- Mineral Grading

- Plastics

- Food

- Fertilizer

- Recycling

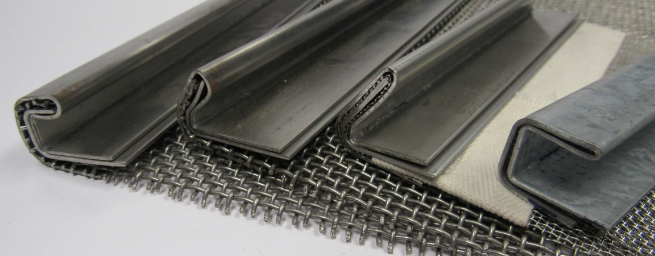

Shaker/Hooked Screens

Shaker/Hooked Screens are often used in the mining and quarrying industries to separate different-sized particles. They can also be used for grading, sorting, and screening materials from soils, coal, and chemicals. Additionally, they are used in agriculture to screen grain or animal feed and for industrial processes such as sifting out impurities from manufactured products.

We offer a wide variety of standard hook profiles to meet your guidelines and needs. Custom profiles are also available up to 120” in length.

We know how important it is for your screens to withstand the demand of any industrial application, which is why we offer options such as backing meshes for additional support.

The construction process for shaker/hooked screens initiates with a comprehensive sequence of tasks: inspecting, measuring, and precisely cutting the necessary materials. Following this, the mesh edges are expertly folded, ensuring neatness and structural integrity. With meticulous attention, all the components are thoughtfully arranged and securely fastened into place. The culmination of this process involves carefully forming the desired hook profile, resulting in a shaker screen that meets the highest quality and performance standards.

Why Choose Universal Wire Cloth Screens

Discover unmatched quality and customization with Universal Wire Cloth’s vibrating, sifter, and shaker screens. Benefit from our years of industry expertise, receiving tailored solutions that excel across diverse applications.

Our commitment to advanced materials, cost-efficiency, and technological innovation ensures screens that outperform expectations. With a client-centric approach, we guide you through options, provide cost-saving insights, and deliver the utmost value. Elevate your projects with screens that represent longevity, adaptability, and a competitive edge.