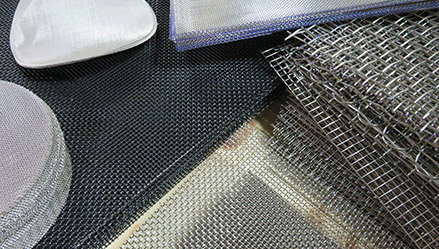

Wire Mesh Products

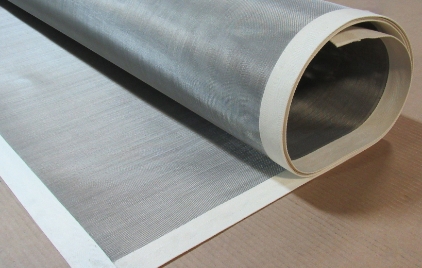

As a supplier as well as a direct to consumer business, we manufacture wire mesh products for numerous industries that range from industrial grade wire cloth for sizing & filtration to security solutions and architectural applications. Whether you are looking for custom woven wire mesh inserts for bridge & walkway infill paneling, slit-to-width rolls of hardware cloth or fully certified test sieves, the quality of our wire mesh products will exceed your expectations.

Our inventory and weaving/welding capacity combined with our fabrication capabilities allow us to produce turnkey products at competitive prices. Our customers receive superior wire mesh goods made to the exact requirements, delivered on-time and on-budget.

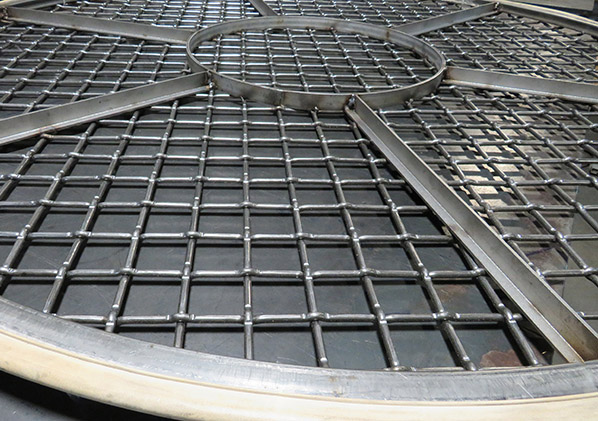

Fabrication Services

Our computer-controlled equipment, in collaboration with the careful eye and craftsmanship of the operator, make our fabrication services top of the line. Before/After each production run, our quality assurance team reviews job descriptions, materials and tooling verifying adherence to strict internal standards providing our customers with the highest caliber result. Our shop features saws, shears, brakes, presses, rollers, and welding machines to accommodate virtually any wire cloth fabrication project. This includes a variety of screen section options with or without edging and cylinder manufacturing.

Top Wire Mesh Manufacturer

Universal Wire Cloth is a wire mesh manufacturer based out of Morrisville, PA.

When it comes to wire cloth, no wire mesh company does it better than Universal Wire Cloth Co. We are a leading wire cloth manufacturer in the US. Our wire cloth is used in various applications, including filtration, sifting, screening, and more. We offer a wide range of wire cloth products, including welded wire mesh, hard wire cloth, and wire mesh cloth.

Why Choose Universal Wire Cloth Company?

There are many reasons to choose Universal Wire Cloth Company as your wire cloth manufacturer. Our products are used in a variety of applications all over the world. We also offer custom manufacturing services to ensure you get the exact product you need for your application.

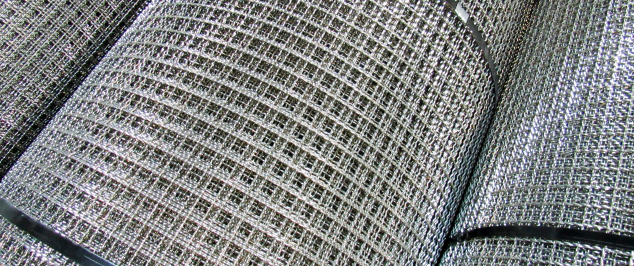

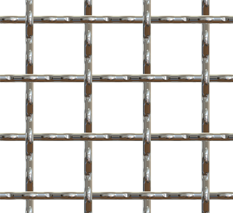

Welded Wire Mesh

As a top wire mesh manufacturer, you can rest assured that our welded wire mesh is made from high-quality steel that is fused together to create a strong, sturdy product. Welded wire mesh is often used in applications where strength and durability are paramount.

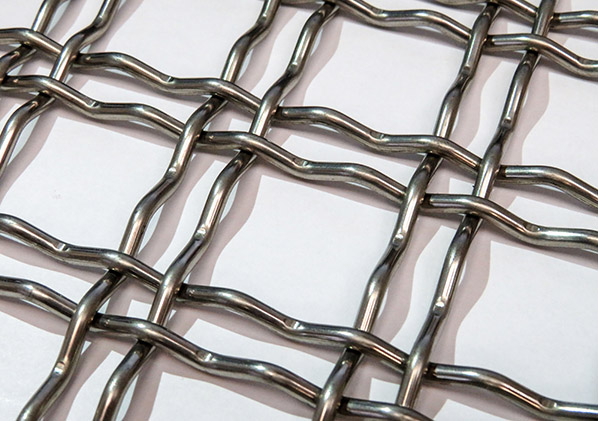

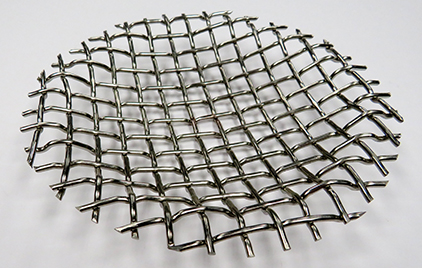

Hard Wire Cloth

Hard wire cloth is made from high-carbon steel that is heat treated to create a harder, stronger product. Hard wire cloth is often used in applications where abrasion resistance is important.

Custom Manufacturing Services

In addition to our standard product offerings, we also offer custom manufacturing services to ensure you get the exact product you need for your application. Our experienced engineers will work with you to design a custom solution that meets your specific needs. Contact us today to learn more about our custom manufacturing services and find out what makes us the best welded wire mesh manufacturer.