OEM Replacement Screens

Did your screen section just break down during the most crucial of production times? We can recreate or even “re-screen” your item to its exact specification with our OEM replacement services. We stock an extensive inventory of wire cloth and parts to fit your original equipment parameters or can strip down your old frame and prep it for new material. With decades of experience and a full-service fabrication shop, Universal Wire Cloth can get you back up and running in no time.

Production output not quite optimal and looking for recommendations? We can also offer suggestions with your current set up to improve performance yield and material duration to provide you with future cost reduction savings. After reviewing current Wire Cloth conditions and your application demands we may be able to recommend alternatives to achieve improved results.

From re-screening your vibratory screens for continued periods of effectiveness to adding backing meshes to sifting screens for increased reinforcement, our OEM replacement service is backed by decades of experience and resources to keep our customers best interests in mind.

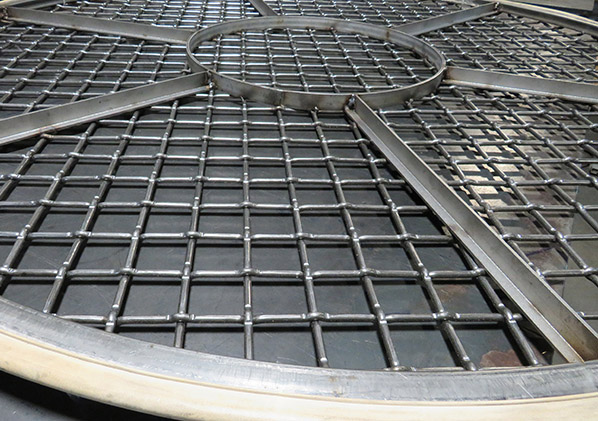

Vibratory Separator Screens

Universal Wire Cloth Co. expertly fabricates both fine wire cloth and coarse mesh bound Vibratory Screens for your particle separation and sizing application needs.

Our rings accurately replace OEM screens equivalent to all the leading manufacturers such as Sweco®, Kason®, & Telsonic® just to name a few. We also can fabricate rectangular frames to your exact requirements.

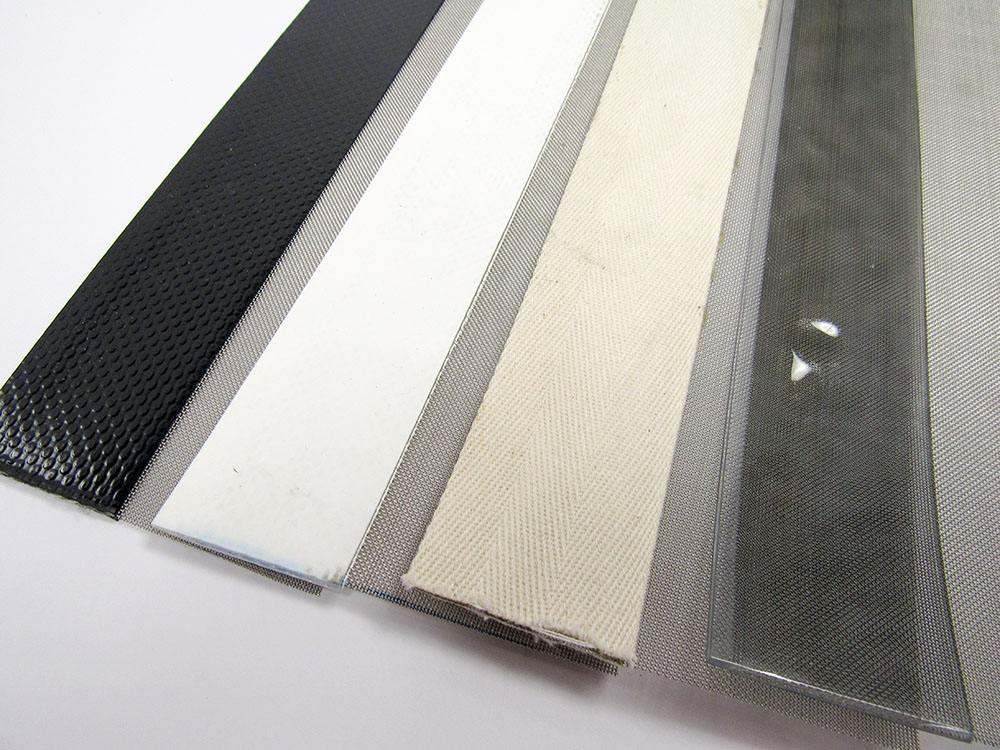

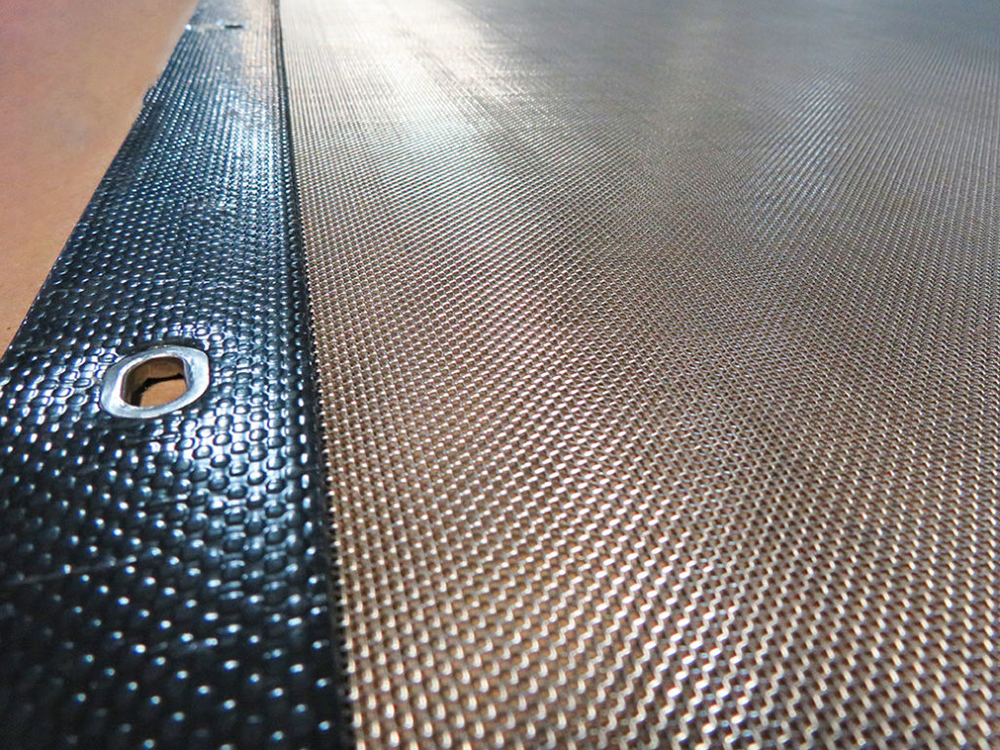

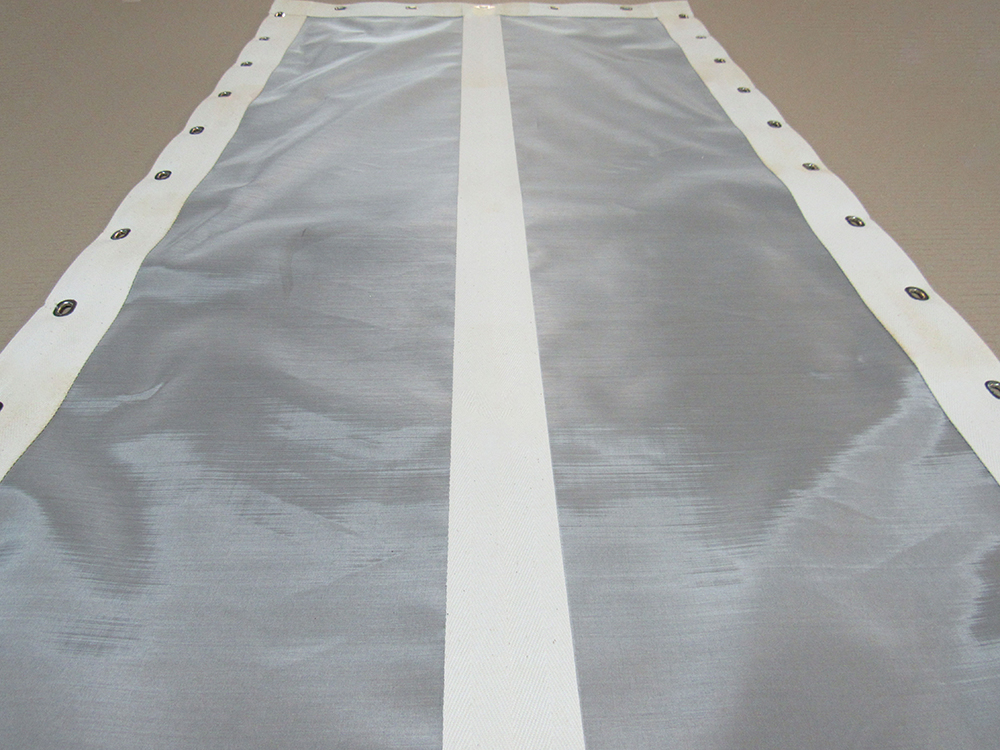

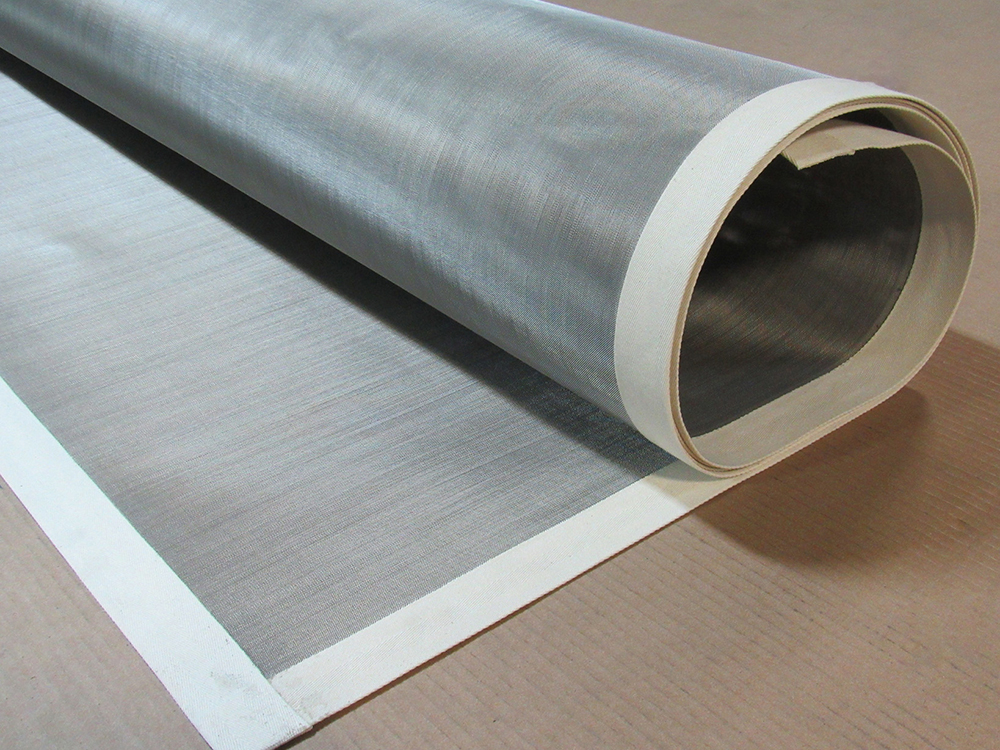

Sifter/Edged Screens

From agricultural & food production to recycling and mineral sorting, our edged screens continue to operate in many essential industries across the country.

We stock an extensive inventory of wire cloth specifications and edging materials to meet your exact equipment requirements. Our Sifter Screens are comparable to all leading manufacturers including the O.E.M such as Rotex®. Additionally, we can produce custom screens, install grommets and add center wear strips upon request.

Please allow us an opportunity to quote your next screening project, you won’t be disappointed!

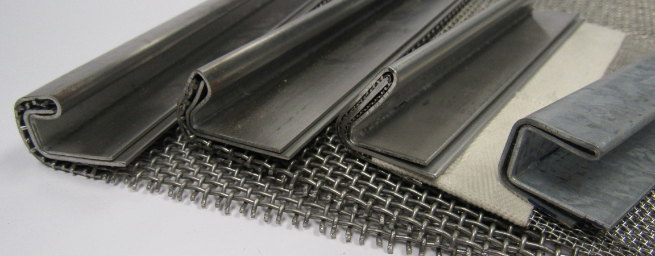

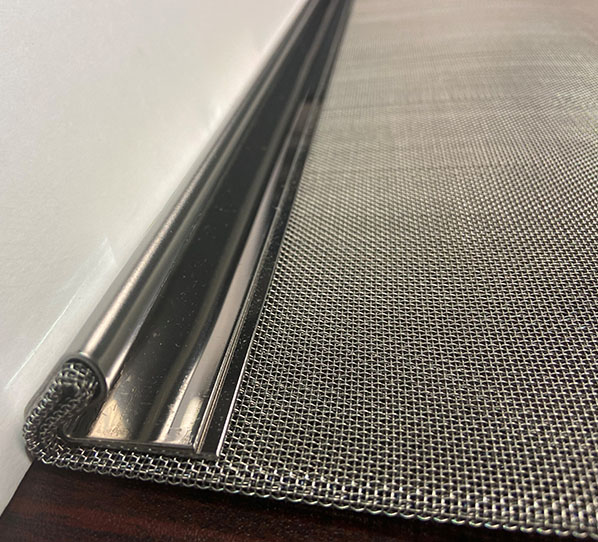

Shaker/Hooked Screens

Our shaker screens come in a variety of hook styles to meet your vibratory and aggregate equipment guidelines comparable to all leading manufacturers such as Midwestern® & Industrial Screen®. Not only do we produce a standard line of hook edges; we can also create a custom profile to fit your distinct sifting and sizing needs. Our stock offers a wide range of mesh specifications to construct the screen section itself and we can reinforce these with backing meshes to withstand the demand of your industrial application.